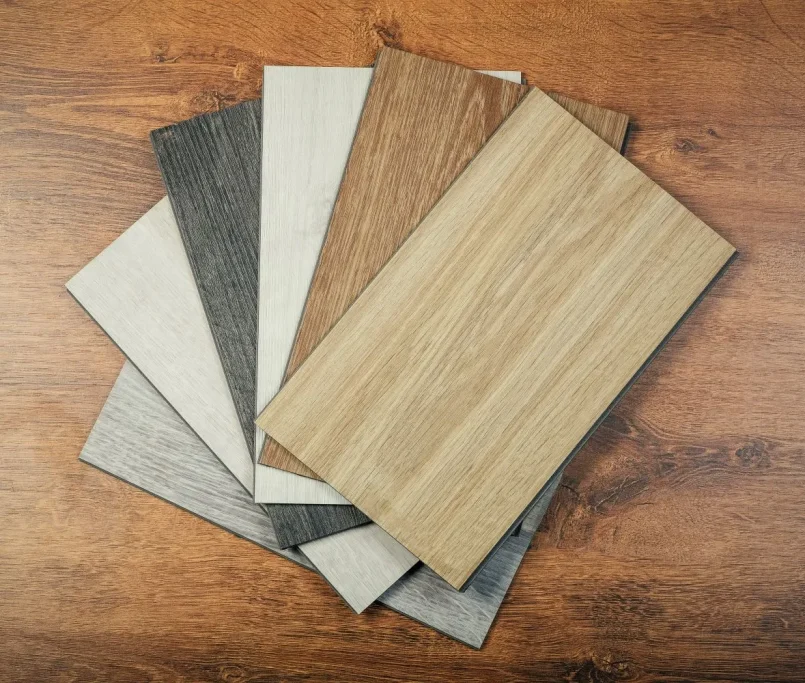

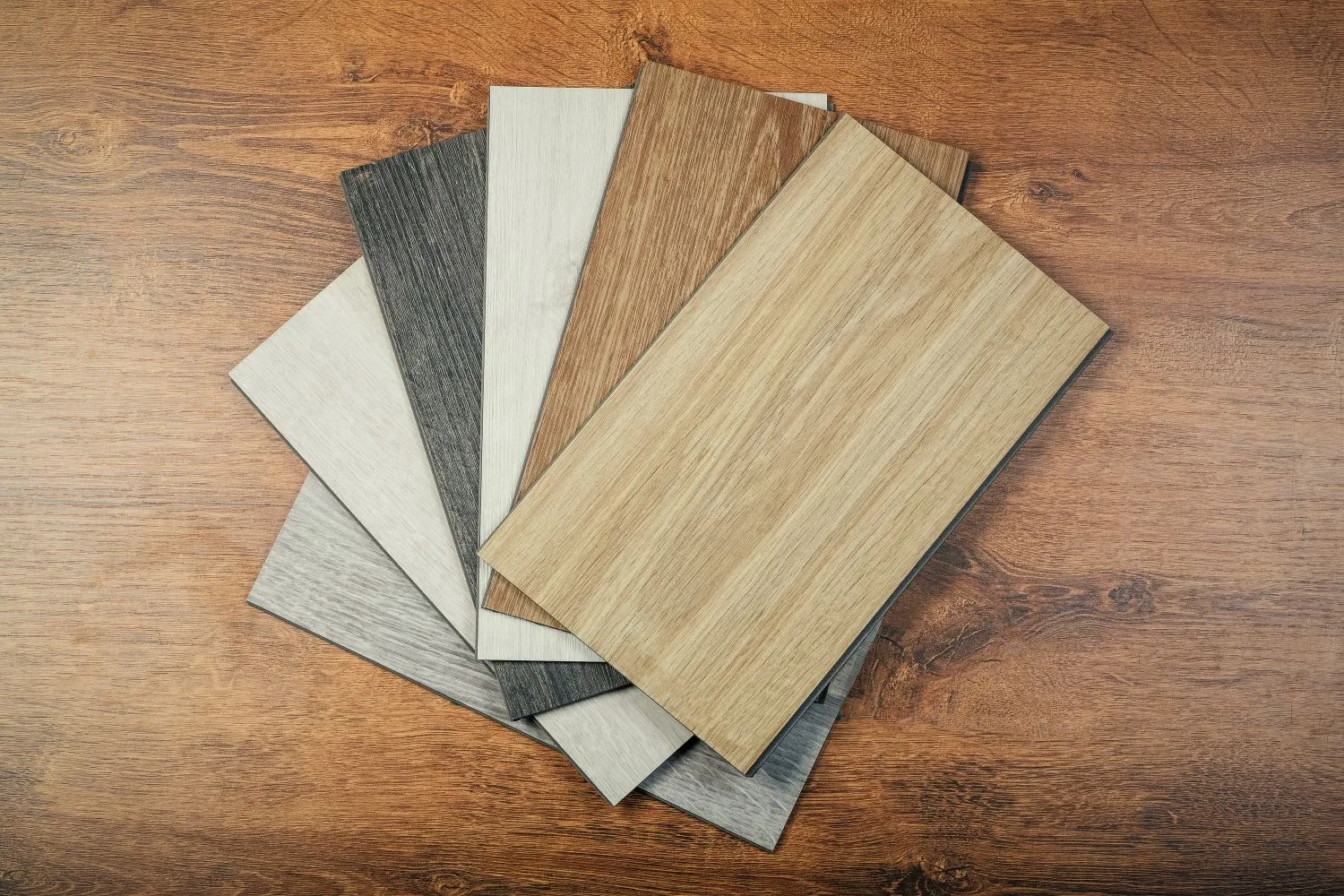

Doors, tables, and other furniture often have decorative veneer sheets affixed to their surfaces. The appearance of a building, whether it be a home or a business, can be greatly improved by carefully selecting the wood species, color, size, and texture. When shopping for veneer sheets, it’s important to remember a few fundamentals. Some of the key takeaways are discussed in this piece. Check it out.

Types of Wood Veneer

Your understanding of the different types of wood veneer is crucial when making a purchasing decision. There are various options available, each with its unique characteristics and applications. It is essential to familiarize yourself with the different types to ensure you make an informed choice. Assume that the type of wood veneer you choose will have a significant impact on the overall look and quality of your project.

| Raw Veneer | Unsanded and unfinished wood veneer sheets |

| Paperback Veneer | Veneer attached to a paper or a flexible backing |

| Laid-Up Veneer | The laid-up veneer is pieces of raw veneer attached together to create larger pieces. |

Raw Veneer

Raw veneer refers to unsanded and unfinished wood veneer sheets. These sheets are extremely thin and require careful handling to prevent damage. The raw veneer is typically used by skilled craftsmen and experienced woodworkers who have the tools and expertise to cut, sand, and finish the veneer to their desired specifications.

Paperback Veneer

A paperback veneer consists of a wood veneer that is attached to a paper or a flexible backing. This type of veneer is more convenient to work with and is often used in DIY projects and smaller woodworking applications. The backing material provides added stability and makes it easier to handle and cut the veneer to size.

Laid-Up Veneer

The term “laid-up veneer” refers to raw veneer that has been joined together to make larger sheets. It’s an excellent choice because it can be customized to your exact specifications in terms of size, style, and form, but it takes a while to make.

Veneer Thickness

Veneers are available in different thicknesses, typically measured in millimeters. The thickness you choose will depend on your project’s requirements, but thinner veneers are generally more flexible and easier to work with. Thinner veneers can easily be bent or shaped to fit the needs of the project, whereas thicker veneers are more rigid and can be used for more structural applications. Additionally, thinner veneers can be easier to glue and finish since they are less prone to cracking or warping.

Veneer Grains

Wood veneers come in a wide range of wood species, each offering unique characteristics and appearances. Some popular types include:

- Oak veneer: Known for its durability and prominent grain patterns, oak veneers are a timeless choice for various projects.

- Walnut veneer: With its rich, dark hues and intricate grain, walnut veneer adds a touch of luxury to any space.

- Cherry veneer: Cherry veneer offers a warm reddish-brown tone that deepens with age, making it an elegant choice for furniture.

- Maple veneer: Maple veneer boasts a smooth, even texture and a pale color that complements modern aesthetics.

- …

Veneer Observability

Front and center are pieces of furniture like the reception desk, the drawing room table, and the front door, The premium quality veneer sheets can be used there whereas cheaper veneers can be used elsewhere, such as the bottoms of cabinets and shelves. Using veneers in such a methodical way ensures the optimum outcomes in terms of function and aesthetics. Veneers are thin sheets of wood that are glued to a substrate, such as particle board. They are much cheaper than solid wood and can be used to create furniture that looks high end but at a fraction of the cost. By using premium quality veneers on pieces that are most visible, the overall look of the furniture is enhanced and it appears more expensive than it actually is.